Digital Printing Expands Services at Pacific Service Center

Pacific Service Center | Portland, Oregon

Pacific Service Center (PSC) in Portland, Oregon began in 1988 as a collision repair company serving the trucking industry. Over the years, PSC has continued its commitment to great service and pricing, adding digital graphics to their list of products. The company’s clients include some of the biggest names in the food services industry; companies such as Coca-Cola, Pepsi Co., McDonald’s, Coors and Budweiser, as well as smaller firms and entrepreneurs count on PSC to keep their vehicles looking sharp.

The vehicle graphics business evolved rapidly for PSC. “At first, customers were coming to us for replacement numbers and stripes,” said Sean Hemak, PSC’s graphics specialist. “Then they began asking for help with logos and graphics.”

To make their graphics work easier, faster and more dynamic, PSC invested in a Roland VersaCAMM VP-540 54” digital printer/cutter. Hemak had used Roland equipment in previous jobs and knew the quality and reliability Roland offers. “I can do all the standard maintenance myself,” said Hemak. “The VersaCAMM can print on a wide variety of materials, and we run it all day, every day.”

“I never know what’s coming at me,” said Hemak. “Some people come in with old, thrashed graphics, and we give them the option of updating or replacing their designs. Others are just starting out and don’t yet know what kind of look they want.” PSC often starts from the ground up with their clients, designing logos and fleet graphics for trucks and vehicle customers. The company handles everything from Smart cars to 53’ rigs, and works on thousands of vehicles each year.

Hemak heads up PSC’s vehicle graphics department with help from Justin Nitz and Stephen Wilson. They oversee each step of the work, bringing on additional people as needed to do graphic removals and installations as well as help with marketing and sales. “We want to really let our clients know we are listening to their needs, and that we’ll be with them from start to finish,” said Hemak.

PSC uses its VersaCAMM to generate all aspects of vehicle graphics, from stickers and decals to window perfing and full wraps. The VersaCAMM’s automated cutting feature can create both perforated and contour cuts, making it a versatile tool for multi-tasking shops like PSC. “We use the perf cut system a lot,” said Hemak. “The print and cut feature is an incredible time saver.”

“The VersaCAMM prints quickly and cleanly, which means my clients have less down time,” said Hemak. “We can get them back to work in 1-2 days, which is really valuable for our trucking clients.”

Hemak has found ways to work creatively with the customized trucking fleets they serve, which often have unique features. For instance, some tractor cabs have a window on one side and not on the other. To create a custom-fit design, Hemak and his staff take pictures of the vehicle and get basic measurements. Then they use software to design graphics and show the client several different concepts on the on-screen vehicle photo. “We can design in a day, then email the client a composite photo of the designs on the actual vehicle,” said Hemak.

Another technique Hemak uses when clients are evaluating graphic designs is to purchase a toy version of the vehicle and install a wrap on the model, to give the client a clearer picture of the finished version. “Customers really appreciate being able to see what the vehicle will look like when we’re done,” said Hemak.

When the client approves a design, Hemak and his team RIP the graphics using Roland’s VersaWorks software and output it to the VersaCAMM for printing and cutting. If needed, Hemak and his crew can have a vehicle wrapped in two days, using one day to build the file and get it approved, and the second to produce and install the graphics. “The VersaCAMM prints quickly and cleanly, which means my clients have less down time,” said Hemak. “We can get them back to work in 1-2 days, which is really valuable for our trucking clients.”

Especially for their collision repair business, Roland’s color matching is key. “We use the color matching to create paint patches,” said Hemak. “The Roland color quality is exceptional. What you see on the screen is what you get.” PSC relies on Roland’s ECO-SOL MAX inks to guarantee consistent quality output.

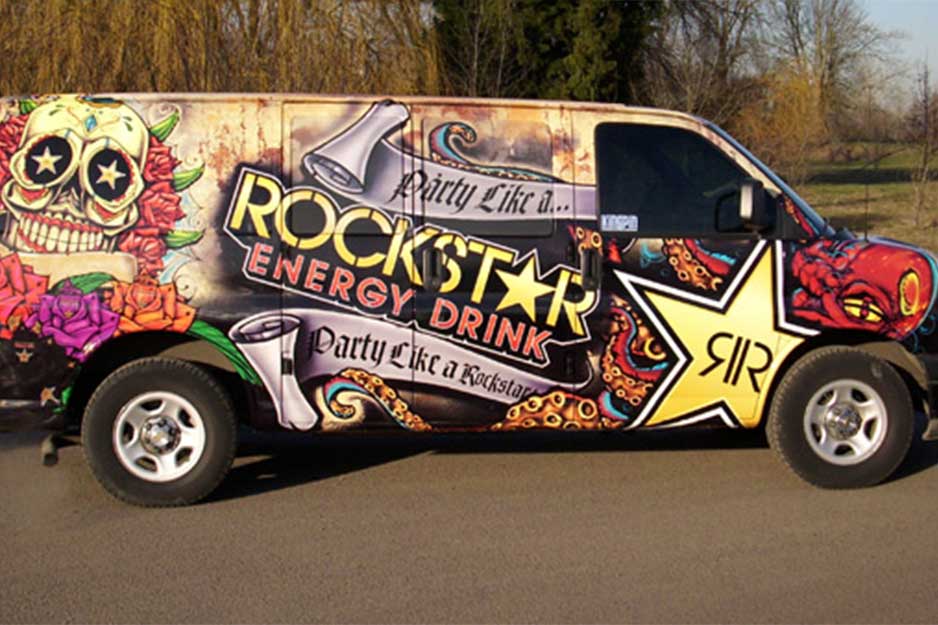

As PSC’s reputation in graphics work has grown, so has its client list. The extent of the design work PSC does “really depends on the client,” said Hemak. Rockstar recently hired PSC to work in conjunction with West Coast Customs in Southern California and a tattoo artist to develop an innovative design for their corporate vehicle. PSC has also done custom work for the Portland Blazers and other local sports organizations. Sometimes, their clients have novel requests, such as a recent project that involved wrapping the interior and exterior of a walk-in freezer for trucking client DPI Specialty Foods. “We used a propane torch to heat that one,” said Hemak.

“Companies have to advertise, and vehicle graphics are a great way to get their message across. Our Roland helps us provide our clients with the graphics they need to succeed,” said Hemak. “After all, service is our middle name.”