Digital Printing Brings Dynamic Success

Dynamic Display | Ronkonkoma, NY

Knowing that the only constant in life is change, Mike Benti built the concept into his business. Benti owns Dynamic Display in Ronkonkoma, New York, a company that has seen its share of changes since its inception over 40 years ago.

Benti’s father founded the business in 1968 as Topps Reprographers, providing neighboring firms with architectural drawings and drafting supplies. In the late 1980s, the Bentis replaced their analog equipment with an inkjet machine, becoming one of the few color-equipped shops in the area, and expanded their offerings to include signage. As the mix of industries in their area changed, Benti began producing trade show graphics, and later moved to large format digital printing. In the late 1990s, they officially changed their name to Dynamic Display, and, in 2003, added a subsidiary, Dynamic Wraps specializing in vehicle, wall, floor and window graphics.

For more than a decade, Benti’s shop has relied on Roland’s technology to see them through the changes. Their current production environment is anchored by a Roland SOLJET PRO II SC-540 54” digital printer/cutters, along with a Roland CAMM-1 PRO vinyl cutter. “One of our Rolands is from the early ‘90s and still running like new,” said Benti. “In ten years, I’ve never had down time on the machine.”

These days, Dynamic Display is focused on trade show graphics, high-end retail signage, and vehicle wraps. They run lean, with a staff of five and two freelance artists to handle all types of design, production and installation.

For their trade show work, Benti and his team either meet with clients directly or work with their clients’ ad agencies and marketing groups to develop designs and build out displays. Dynamic Display takes pride in producing high-quality graphics on styrene film or smooth vinyl for their pop ups and banner displays. Since the SOLJET prints directly onto adhesive material, they can eliminate several installation steps and provide a cost-effective option for their clients.

“One of our Rolands is from the early '90s and still running like new,” said Benti. “In ten years, I've never had down time on the machine.”

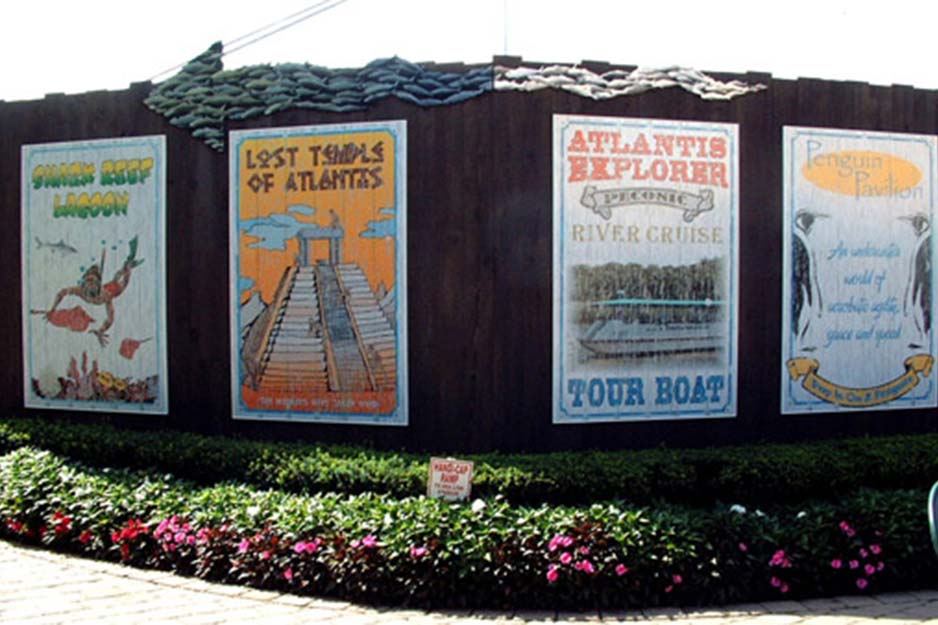

Although their trade show business is still strong, these days many of Benti’s clients are economizing by reusing trade show materials rather than creating new displays for every show. Responding to this trend, Benti has restructured his business plan to focus more strongly on creating retail signage for high-end clients, including seasonal and indoor display graphics. Their marketing efforts have paid off with clients such as Friendly’s, Starbucks and Red Mango, as well as Zoo York, an emerging brand of skateboard clothing and supplies.

Benti notes that especially with indoor retail signage, the color quality is key. Benti uses Roland’s ECO-SOL MAX inks to guarantee color matching and runs these prints at speeds generally reserved for photorealistic images and fine art. The result is prints that win clients. “Customers see these prints at very close range, and the colors need to be right on for the images to look appealing,” said Benti.

Benti recalled his introductory presentation to the marketing director of Friendly’s. Before their meeting, the director had sent Benti an artwork file comprised of several individual food items, including an egg sandwich and a glass of orange juice, and asked Benti to design a banner. “When I unrolled our design, the director said ‘Those eggs look like I could eat them right off the banner’ and I knew we’d done well,” said Benti. “That one print resulted in an important and ongoing client relationship.”

Dynamic Display’s vehicle wrap division, Dynamic Wraps, is also experiencing success in the new economy. “At first, everyone thought vehicle wraps were a fad, but we could see that it was a great form of advertising,” said Benti. Now, they wrap everything from trucks to helmets to JetSkis. “The only things we haven’t stuck material on are oil and water,” laughs Benti.

Dynamic’s vehicle wrap staff is kept busy by fleet and individual orders, including wrapping vehicles for Verizon Wireless. They also do wraps for the building and construction industry, food companies, flower shops, service entrepreneurs and private clients. Benti’s staff creates the wraps in Adobe Creative Suite, then uses Roland’s VersaWorks RIP software to output the designs to the SOLJET. In addition to trucks and fleet vehicles, they report increasing orders for wraps on eco-friendly models such as the MINI Cooper and smart fortwo cars.

“In this industry, you have to move with the trends or your business will die,” said Benti. “We reassess our strategy regularly so we can continue to provide our clients with services that are relevant for their business.”